I’m welcomed by Brice, the current distiller – who will soon be taken over by Maureen – who suggests I begin my visit by observing the agricultural work of the workers on the estate. We’re going to follow the different phases, from cutting to crushing the cane, the prelude to distillation. Brice takes the opportunity to explain the techniques used, while telling me about the renaissance of H.B.S. rums.

Distillation8 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Distillation8 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy Decoupedelacanneasucre3 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Decoupedelacanneasucre3 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy Canneasucre Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Canneasucre Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy“We use only 3 hectares of sugar cane out of the 60 planted on the estate (the other 57 are harvested by J.M). At H.B.S, the sugar cane is cut by hand, and we change plots regularly. With only two cutting points, hand-harvesting gives clean, sugar-laden cane and different tones to our rums. “

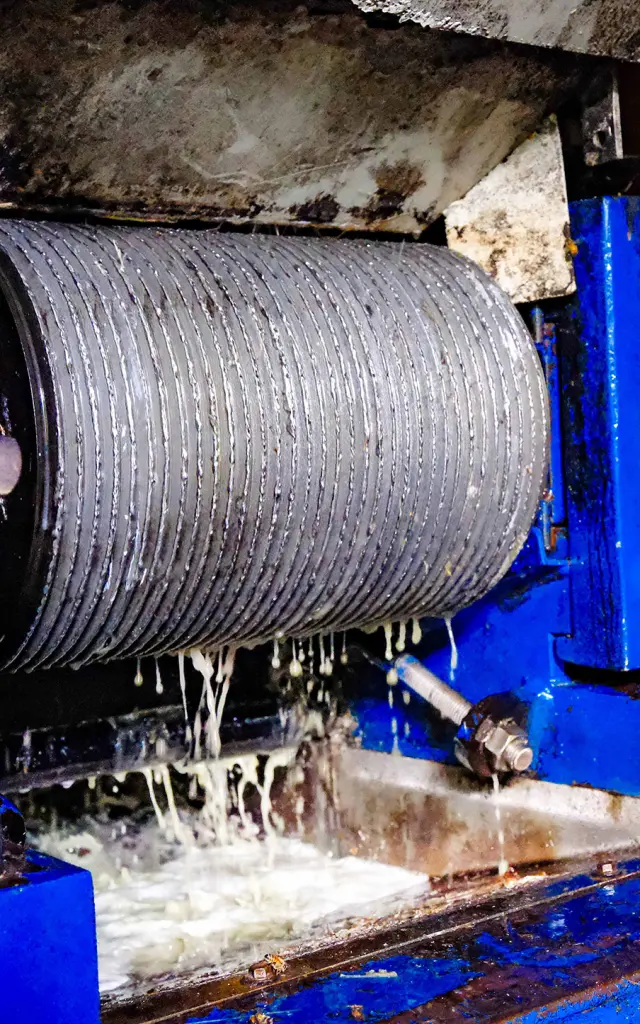

In the field, Christopher cuts the sugar cane, while his two colleagues Patrice and Stéphane pick it up and load it onto the cart. To supply the distillery on a daily basis, two carts are needed (around 1.2 tons of sugar cane). The cane is transported to the distillery by tractor. They then press and grind it in a Brazilian-type mill to extract the maximum amount of juice (vesou). “We make two rotations a day and distill 4 times a week all year round: Monday, Wednesday, Thursday and Friday. “

Decoupedelacanneasucre2 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Decoupedelacanneasucre2 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy Decoupedelacanneasucre4 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Decoupedelacanneasucre4 Distillerie Hbs Habitationbeausejour Grandriviere Martinique CopyProduction of H.B.S. rums

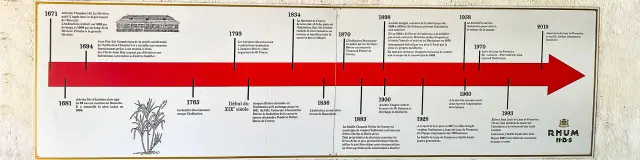

Cane crushing

“The De Lucy family, owners of Habitation Beauséjour and H.B.S. rums, replanted cane after bananas were abandoned in 2007, and decided to relaunch agricultural rum production. We are not part of the AOC, as we distill in alembics rather than Creole columns. This means we can harvest and produce all year round. This suits our small production very well! “

Broyage2 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Broyage2 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy Broyage Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

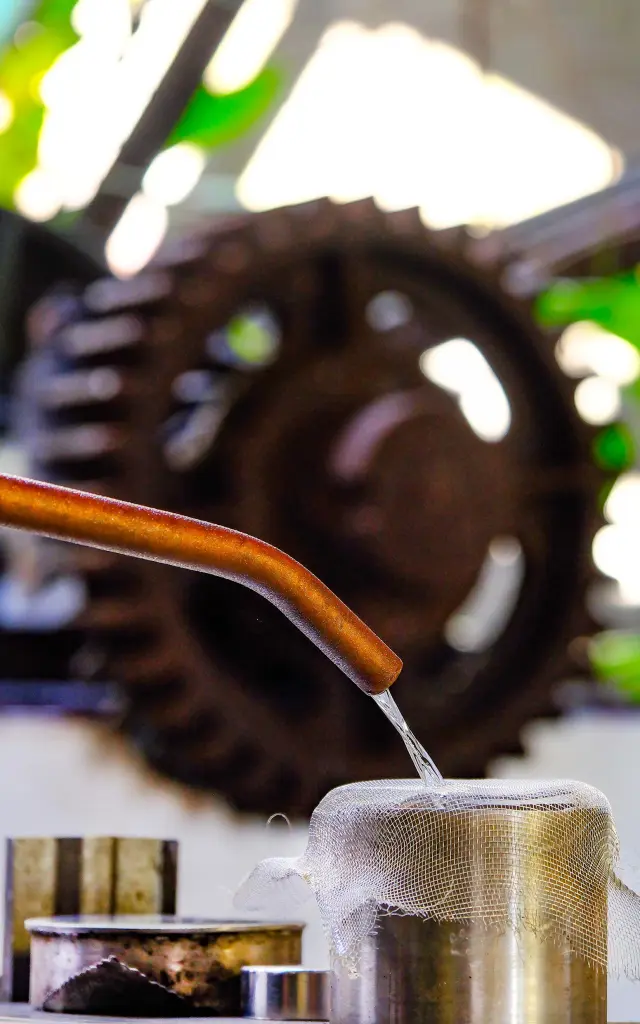

Broyage Distillerie Hbs Habitationbeausejour Grandriviere Martinique CopyStill distillation

880 liters of cane juice (still capacity) are first stored in a large tank after crushing, before being transported to the distillation room. The cane wine rests and ferments for 48 hours before entering the still, which will be manufactured in the Gers region in 2019. As with cognac or armagnac, the wine is heated and produces vapors, giving an alcohol titrating close to 30° in the swan neck.

Distillation6 Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Distillation6 Distillerie Hbs Habitationbeausejour Grandriviere Martinique CopyAging

“I then run this juice through a 9-tray concentration column to increase the sugar concentration and raise the alcohol content. With our 880 L still, I obtain 75 L of rum. Part of it is kept in stainless steel vats for 6 months, during which time I add water until I obtain the desired titration (53° at H.B.S.). A small part is reduced in dames jeannes (we have 13 of them) for our limited-edition white rum, an original feature that adds a great deal of roundness! In all, it takes around 9 months from cutting the cane to bottling. The rest of the white rum is aged in oak barrels.

Damejeannes Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Damejeannes Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy Damejeannes3 Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Damejeannes3 Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy Futs Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Futs Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy Futs2 Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Futs2 Rhum Distillerie Hbs Habitationbeausejour Grandriviere Martinique CopyVisit and Tasting

Roueahaube Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Roueahaube Distillerie Hbs Habitationbeausejour Grandriviere Martinique CopyThe tour of the current installations and the buildings of the old distillery is free, and you can wander around and get your bearings thanks to the map and explanatory panels tracing the history of the dwelling and the rum-making process. It’s a small distillery, so you really feel in the “thick of things” and the weight of history. There’s also a museum room where you can see a number of objects from the past, including a waterwheel.

Distillerie2 Hbs Habitationbeausejour Grandriviere Martinique Copy

Distillerie2 Hbs Habitationbeausejour Grandriviere Martinique CopyH.B.S. Rums

After all this explanation and immersion in the production site, it’s time for a tasting! Brice introduces me to the young range of H.B.S. rums. The brand now has 3 white rum cuvées: “Cuvée du Voyageur”, “Cuvée Dame Jeanne” and a “Brut d’alambic“.

Rhums Distillerie Hbs Habitationbeausejour Grandriviere Martinique Copy

Rhums Distillerie Hbs Habitationbeausejour Grandriviere Martinique CopyI thank Brice, who accompanied me throughout my visit, and enjoy the view one last time before taking the road back into the rainforest.

A moment out of time!

Habitationbeausejour Grandriviere Martinique Copy

Habitationbeausejour Grandriviere Martinique CopyThe main house is a private residence and is not open to the public. Don’t miss the Heritage Days to discover the estate and its gardens, which are open to the public on that day! Date: September 21 and 22, 2024.

We' d like to hear from you!

* Alcohol abuse is dangerous for your health, and should be consumed in moderation.